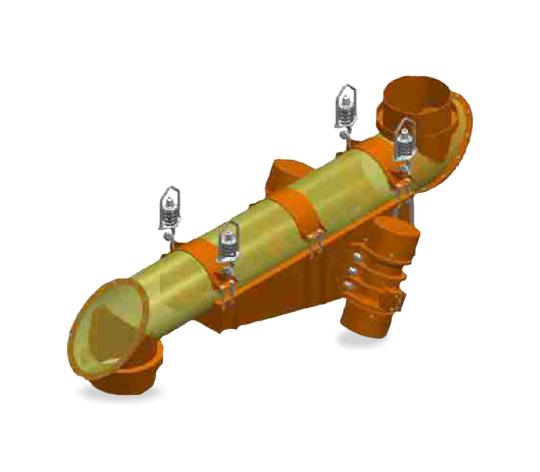

Mechanical Vibratory Feeder

Controlled Material Feeding & Dosing System

Engineered for uniform, continuous, and controlled feeding of bulk materials into downstream processing equipment.

The Mechanical Vibratory Feeder is designed to ensure consistent and regulated feeding of bulk materials such as minerals, powders, granules, and aggregates. It prevents jamming, maintains steady flow, and enhances productivity in processing lines including crushers, conveyors, screens, and mixers.

Powered by unbalanced motor-driven vibration, it generates linear motion that smoothly conveys material across the tray. Feed rate can be easily adjusted by controlling amplitude and frequency, making it ideal for applications requiring precision feeding.

With rugged construction, low energy consumption, and reliable continuous operation, Mechanical Vibratory Feeders are widely used in stone processing, chemicals, food, fertilizer, and powder handling industries.

Technical Specifications

| Specification | Details |

|---|---|

| Capacity | 500 kg/hr – 100 TPH |

| Tray Width | 150 – 2000 mm |

| Motor Capacity | 0.5 – 5 HP |

| Vibration Source | Unbalanced Motors |

| Feeding Control | Adjustable Amplitude & Frequency |

| Material of Construction | MS / SS |

Key Features

- Uniform material flow without clogging

- Adjustable feed rate for precise dosing

- Reliable unbalanced motor vibration drive

- Low power consumption with high efficiency

- Suitable for continuous 24/7 operation

- Optional wear-resistant tray lining

Applications

- Stone & Minerals: Feeding crushers, screens & conveyors

- Food Industry: Grains, powders, granular products

- Chemical Processing: Fine powders & granules

- Fertilizer Plants: Powder & granule feeding

- General Industries: Controlled feeding for mixers & packaging lines